Contact:Mr.Liao (+86-13929873515)

Mr.Mo (+86-13929865786)

Tel:0758-8515892

Fax:0758-8515892

Email: zqdx@dxvacuum.com

Address:Jindu industry zone,Gaoyao,Zhaoqing city,Guangdong,China

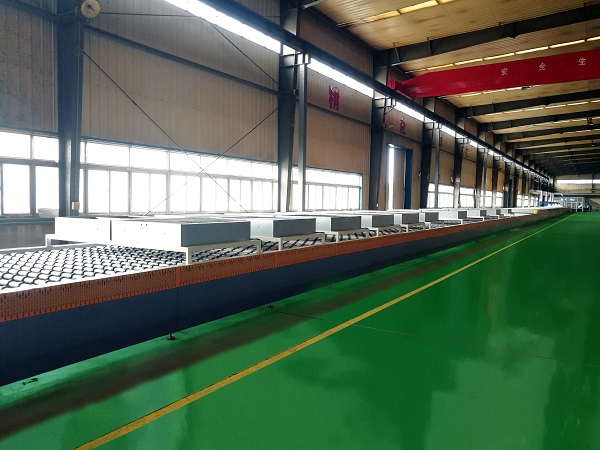

Silver mirror processing process: glass cleaning before plating, sensitization, silver plating, copper plating, air-blow drying, pre-heating and baking, primer, primer drying, finish paint, finish paint drying, strong wind cooling, mirror cleaning after plating, air-blow drying all processes in the production line automatic one-time completion. The silver film was reduced on the glass surface by on-line chemical spray plating. The same method is used to reduce the copper film on the surface of the silver layer (to protect the silver layer from corrosion). Compared with aluminum mirror, silver mirror has the advantages of high reflectivity, good clarity, corrosion resistance and strong adhesion. In recent years, we have successfully developed antique silver mirror production line, copper free environmental protection silver mirror line with stronger corrosion resistance and solar thermal mirror production line.

Main Feature:

◆Introduction of foreign advanced silver mirror production formula and technology to ensure the stable quality of the silver mirror.

◆Nozzle, metering pump and other main components are imported high-quality products.

◆Equipped with automatic loading and unloading, reduce the labor intensity of workers.

◆The speed of glass transmission is controlled by inverter, which is easy to adjust.

◆Gold-plated infrared heating tube is adopted for drying and heating, which is energy-saving and efficient

◆Adopt programmable controller (PLC), touch screen (HMI) man-machine control interface, easy to operate, manual/automatic control freely switch.

Production line model:

DXY-2436 DXY-1824 DXY-1218

Workpiece size(mm):

W2400XL3660 W1830XL2440 W1220XL1830

Note:

Production line size and configuration can be customized according to customer requirements